For use with Laminate Floors only.

Inspect the job site carefully before you begin the installation. Some conditions require specific installation methods. A level, flat, clean, dry, and firm subfloor is always necessary. All L.W. Mountain, Inc. products are manufactured in accordance with accepted industry standards. If the material is not acceptable, do not install it and contact the seller immediately.

Climate and Pre-installation Procedures

• Material should be stored on the job site in rooms where installation is to occur.

• Garages and exterior patios are not suitable for storing laminate flooring.

• DO NOT remove the product from the cartons.

• DO NOT open just the ends of the cartons.

• HVAC systems MUST be installed and operating before the flooring is delivered to the jobsite.

• All concrete, masonry, framing members, drywall, paint and other “wet” work should be thoroughly dry.

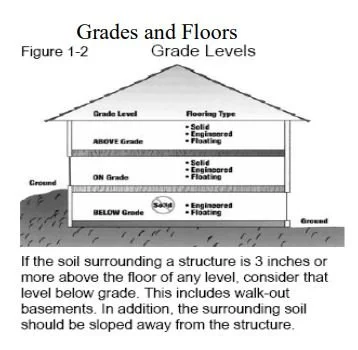

• Exterior Grading should be complete with surface drainage offering a minimum drop of 3’ in 10’.

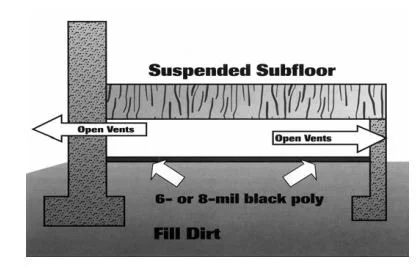

• Crawl spaces must be a minimum of 24” from the ground to the underside of the joists. A ground cover of 6-8 mil black polyethylene film is essential as a vapor barrier with joints lapped six inches and taped. The crawl space should have perimeter venting equal to 1.5% of the crawl space square footage.